Due to its high demand from collectors and fans, artists—both independent and signed—have been releasing singles and albums on vinyl records.

This impact from the vinyl comeback has been a blessing for many, however, some found it burdensome. We all know how the vinyl record is an expensive piece of audio format, even back in the day.

It’s costly because vinyl takes time, effort, and money to produce.

Not only that, some materials needed for its production are expensive, so we can’t blame pressing plants for pricing them like that.

Now with more design variation and customization on both the format’s packaging and the vinyl record itself, it just became more costly.

With the pandemic going on, money is scarce for full-time indie musicians, making it harder for them to release in the format. But worry no more.

Pressing plants have been offering short run vinyl pressings for as low as 1 unit, but that would be wasting time right? So why not try having a vinyl pressing for 100 copies? Here are 10 steps to order:

Table of Contents

Step 1. RECORD YOUR WELL-PICKED TRACK/S

Before ordering for a vinyl pressing, you should, of course, record the tracks you’d want to be pressed on them.

While recording, keep in mind that high sibilance can cause distortions while the vinyl is being played on the turntable.

What is this high sibilance I’m talking about? It’s that emphasis on letters like “s”, “f”, and “t”. So try with all your might to make sure to avoid giving too much emphasis on those while recording your tracks.

Step 2. HAVE THEM MASTERED FOR VINYL

Another step you have to take before the actual pressing of those custom vinyl records is to have your tracks mastered for vinyl. Yes, there is a different master for vinyl. It’s not the usual digital mastering so looking for a good vinyl master engineer would be quite a challenge. Good luck with that.

Step 3. DECIDE ON THE VINYL PACKAGING

While doing all those track recording and master engineer seeking, you have to decide on what vinyl packaging you’ll want for your custom vinyl records.

It helps you know the amount of money you will need to spend. You’ve got tons of options to pick from: single jacket, gatefold jacket, trifold jacket, blank paper inner sleeves, antistatic inner sleeves, printed inner sleeves, and many more.

Step 4. CONCEPTUALIZE YOUR VINYL ALBUM COVER

Another thing to worry about is the cover of the vinyl album jacket. After choosing the track/s you can already make a design based on those. Try to make it pretty and unique, something that would attract and persuade not just your fans but also other people to buy your album.

Step 5. DESIGN YOUR VINYL RECORD

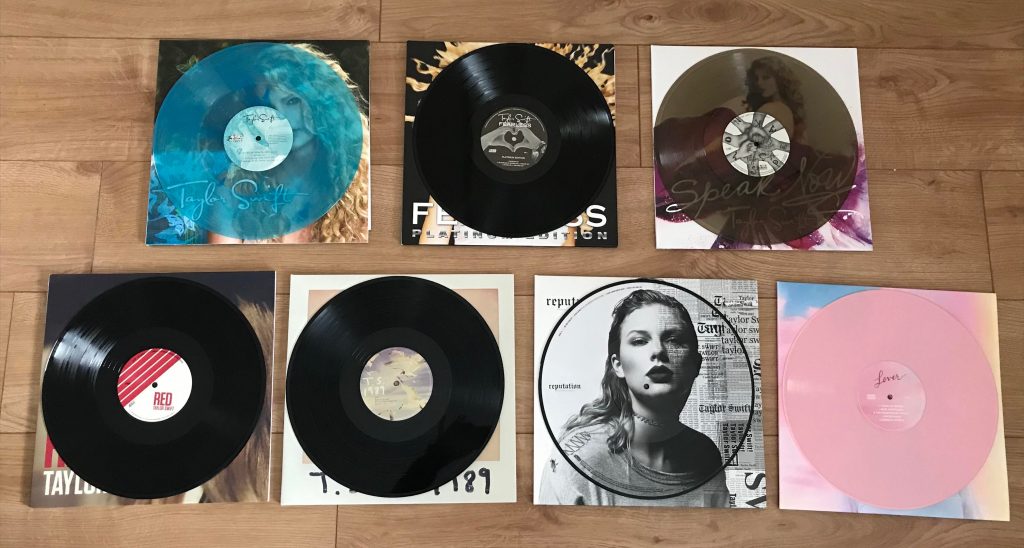

Yes, you can now design your vinyl records with whatever you want. Unlike in the earlier years if the format with only black as the only color, we now have customization options available. You can have colored custom vinyl records that can be monocolored, bicolored, or multicolored.

Clear vinyl records, glow-in-the-dark ones, and even picture discs like the one above are possible now. You can also add in different materials for your design such as leaves, glitters, blood and more.

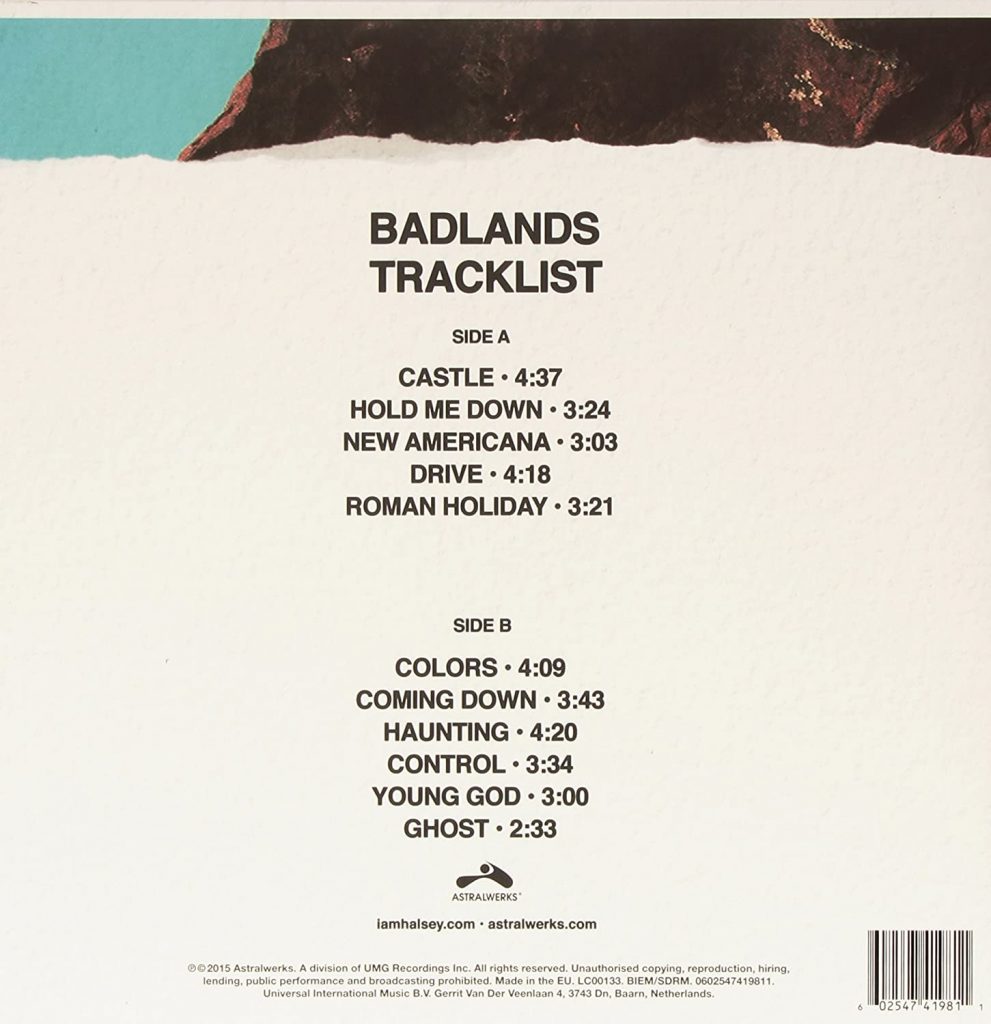

Step 6. COMPOSE YOUR TRACK LIST WELL

This is a very important step if you want to have a flawless vinyl record album. Vinyl records have physical limitations and one of them is that their inner grooves are prone to distortion.

What can you do to avoid having those distortions? Have your information-heavy tracks on the outer grooves and your mellower ones on the inner ones. That’ll help avoid skipping tracks.

Step 7. ORDER FROM A TRUSTED PRESSING PLANT

So yeah, after going through all of those things, we have finally come to this. You have to make sure that the pressing plant you’ve ordered from has a good reputation and is a trusted one.

You can’t risk any major fallbacks or that will surely cost you big time. Look for a pressing plant that offers a short run vinyl pressing 100 copies to save some money too.

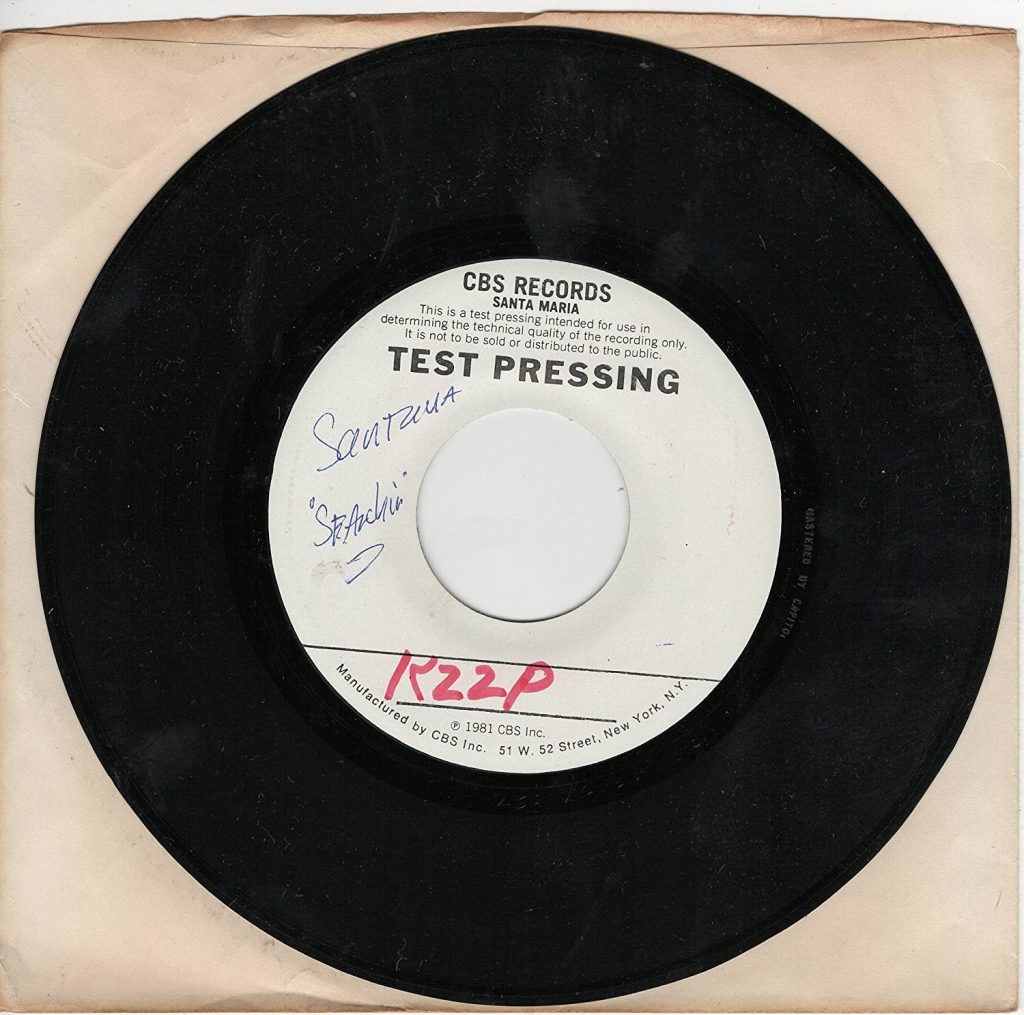

Step 8. THOROUGHLY CHECK YOUR TEST PRESSING

After placing your order, you’ll have to wait for the test pressing of your vinyl. When it arrives, make sure to thoroughly check it. Listen to it well and look for any distortions or problems. It’s not that you don’t trust your pressing plant, it’s just to make sure nothing goes wrong.

Step 9. GIVE YOUR GO SIGNAL

If you’re done listening to the test pressing and found no fault whatsoever, then you can give your pressing plant your go signal. After the go signal they’ll start producing your vinyl records for real so that test pressing will be your last chance to correct the faults. If you found some, then address it to your pressing plant immediately.

Step 10. WAIT FOR YOUR CUSTOM VINYL RECORDS

And the last step would be to wait for your custom vinyl records. Vinyl record production can be quite long so brace yourself for a great deal of waiting. But if you had vinyl pressing 100 copies, then there’s no need to have that prolonged waiting game. I bet you’ll receive those 100 copies in around one to two weeks after you go signal, so there’s no need to wait for long.

So that’s it! These are the 10 steps you need to do to order your custom vinyl records. If you’re planning on ordering your custom vinyl records, or if you are already looking for a pressing plant to press your vinyl record, then you can order here and get an instant quote.

________________________________________________________________________

James Hill is a veteran of the music industry. He first worked at Warner Reprise Records then later joined Interscope/ Geffen Records where he managed producers and songwriters and got his first platinum record for Keyshia Cole’s The Way It Is. He is now helping indie artists with branding and manufacturing through his company Unified Manufacturing, a CD/DVD, custom vinyl records and merch company in LA.